Circular Disc Industrial magnet pure permanent magnet

Circular Disc Industrial Magnet, as a pure permanent magnet, has strong magnetic force and long-term stable magnetism. This magnet adopts a round disc design and is compact in structure, making it easy to install and use. It is made of high-quality magnetic materials, has excellent magnetic and physical properties, and can withstand harsh environments such as high temperature and high pressure. Circular Disc Industrial Magnet is widely used in industrial automation, machinery manufacturing, electronic equipment and other fields, such as the manufacturing and maintenance of key components such as motors, sensors, and instruments. Its powerful magnetic force can stably absorb and fix ferromagnetic substances, achieving precise positioning and operation.

Keyword:

Circular Disc Industrial magnet pure permanent magnet

Classification:

Pure Permanent Magnet

Hot Products

|

Grade |

Remanence Induction |

Coercivity |

Intrinsic |

๋Maximum Energy |

Working |

Density |

||||

|

Br |

HcB |

HcJ |

(BH)max |

Tw |

ρ |

|||||

|

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m³ |

MGOe |

℃ |

g/cm3 |

|

|

General Process |

||||||||||

|

N38 |

1.23-1.30 |

12.3-13.0 |

≥876 |

≥11 |

≥955 |

≥12 |

287-318 |

36-40 |

≤80 |

≥7.5 |

|

N40 |

1.26-1.32 |

12.6-13.2 |

≥876 |

≥11 |

≥955 |

≥12 |

302-334 |

38-42 |

≤80 |

≥7.5 |

|

N42 |

1.29-1.35 |

12.9-13.5 |

≥876 |

≥11 |

≥955 |

≥12 |

318-350 |

40-44 |

≤80 |

≥7.5 |

|

N45 |

1.32-1.38 |

13.2-13.8 |

≥876 |

≥11 |

≥955 |

≥12 |

334-366 |

42-46 |

≤80 |

≥7.5 |

|

N48 |

1.37-1.43 |

13.7-14.3 |

≥876 |

≥11 |

≥955 |

≥12 |

358-390 |

45-49 |

≤80 |

≥7.5 |

|

N50 |

1.40-1.45 |

14.0-14.5 |

≥876 |

≥11 |

≥955 |

≥12 |

374-406 |

47-51 |

≤80 |

≥7.5 |

|

N52 |

1.42-1.48 |

14.2-14.8 |

≥836 |

≥10.5 |

≥876 |

≥11 |

390-422 |

49-53 |

≤80 |

≥7.5 |

|

N55 |

1.46-1.51 |

14.6-15.1 |

≥860 |

≥10.8 |

≥955 |

≥12 |

406-438 |

51-55 |

≤80 |

≥7.5 |

|

N38M |

1.23-1.30 |

12.3-13.0 |

≥915 |

≥11.5 |

≥1114 |

≥14 |

287-318 |

36-40 |

≤100 |

≥7.5 |

|

N40M |

1.26-1.32 |

12.6-13.2 |

≥939 |

≥11.8 |

≥1114 |

≥14 |

302-334 |

38-42 |

≤100 |

≥7.5 |

|

N42M |

1.29-1.35 |

12.9-13.5 |

≥963 |

≥12.1 |

≥1114 |

≥14 |

318-350 |

40-44 |

≤100 |

≥7.5 |

|

N45M |

1.32-1.38 |

13.2-13.8 |

≥987 |

≥12.4 |

≥1114 |

≥14 |

334-366 |

42-46 |

≤100 |

≥7.5 |

|

N48M |

1.37-1.43 |

13.7-14.3 |

≥1019 |

≥12.8 |

≥1114 |

≥14 |

358-390 |

45-49 |

≤100 |

≥7.5 |

|

N50M |

1.40-1.45 |

14.0-14.5 |

≥1043 |

≥13.1 |

≥1114 |

≥14 |

374-406 |

47-51 |

≤100 |

≥7.5 |

|

N52M |

1.42-1.48 |

14.2-14.8 |

≥1059 |

≥13.3 |

≥1114 |

≥14 |

390-422 |

49-53 |

≤100 |

≥7.5 |

|

N54M |

1.46-1.51 |

14.6-15.1 |

≥995 |

≥12.5 |

≥1035 |

≥13 |

406-438 |

51-55 |

≤100 |

≥7.5 |

|

N35H |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥1353 |

≥17 |

263-295 |

33-37 |

≤120 |

≥7.5 |

|

N38H |

1.23-1.30 |

12.3-13.0 |

≥915 |

≥11.5 |

≥1353 |

≥17 |

286-318 |

36-40 |

≤120 |

≥7.5 |

|

N40H |

1.26-1.32 |

12.6-13.2 |

≥939 |

≥11.8 |

≥1353 |

≥17 |

302-334 |

38-42 |

≤120 |

≥7.5 |

|

N42H |

1.29-1.35 |

12.9-13.5 |

≥963 |

≥12.1 |

≥1353 |

≥17 |

318-350 |

40-44 |

≤120 |

≥7.5 |

|

N45H |

1.32-1.38 |

13.2-13.8 |

≥987 |

≥12.4 |

≥1353 |

≥17 |

334-366 |

42-46 |

≤120 |

≥7.5 |

|

N48H |

1.37-1.43 |

13.7-14.3 |

≥1011 |

≥12.7 |

≥1353 |

≥17 |

358-390 |

45-49 |

≤120 |

≥7.5 |

|

N50H |

1.40-1.45 |

14.0-14.5 |

≥1027 |

≥12.9 |

≥1353 |

≥17 |

374-406 |

47-51 |

≤120 |

≥7.5 |

|

N52H |

1.42-1.48 |

14.2-14.8 |

≥1059 |

≥13.3 |

≥1353 |

≥17 |

390-422 |

49-53 |

≤120 |

≥7.5 |

|

N33SH |

1.14-1.21 |

11.4-12.1 |

≥852 |

≥10.7 |

≥1592 |

≥20 |

247-279 |

31-35 |

≤150 |

≥7.5 |

|

N35SH |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥1592 |

≥20 |

263-295 |

33-37 |

≤150 |

≥7.5 |

|

N38SH |

1.23-1.29 |

12.3-12.9 |

≥915 |

≥11.5 |

≥1592 |

≥20 |

287-318 |

36-40 |

≤150 |

≥7.5 |

|

N40SH |

1.26-1.32 |

12.6-13.2 |

≥939 |

≥11.8 |

≥1592 |

≥20 |

302-334 |

38-42 |

≤150 |

≥7.5 |

|

N42SH |

1.29-1.35 |

12.9-13.5 |

≥963 |

≥12.1 |

≥1592 |

≥20 |

318-350 |

40-44 |

≤150 |

≥7.5 |

|

N45SH |

1.32-1.38 |

13.2-13.8 |

≥987 |

≥12.4 |

≥1592 |

≥20 |

334-366 |

42-46 |

≤150 |

≥7.5 |

|

to be conRnued |

||||||||||

|

Grade |

Remanence Induction |

Coercivity |

Intrinsic Coercivity |

Maximum Energy product |

WorkingTemperature |

Density |

||||

|

Br |

HcB |

HcJ |

(BH)max |

Tw |

ρ |

|||||

|

Grade |

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m³ |

MGOe |

℃ |

g/cm3 |

|

N48SH |

1.37-1.43 |

13.7-14.3 |

≥1011 |

≥12.7 |

≥1592 |

≥20 |

358-390 |

45-49 |

≤150 |

≥7.5 |

|

N50SH |

1.40-1.45 |

14.0-14.5 |

≥1027 |

≥12.9 |

≥1592 |

≥20 |

374-406 |

47-51 |

≤150 |

≥7.5 |

|

N52SH |

1.42-1.48 |

14.2-14.8 |

≥1035 |

≥13 |

≥1512 |

≥19 |

390-422 |

49-53 |

≤150 |

≥7.5 |

|

N30UH |

1.08-1.13 |

10.8-11.3 |

≥796 |

≥10.0 |

≥1990 |

≥25 |

223-255 |

28-31 |

≤180 |

≥7.5 |

|

N33UH |

1.14-1.18 |

11.4-11.8 |

≥852 |

≥10.5 |

≥1990 |

≥25 |

247-279 |

31-35 |

≤180 |

≥7.5 |

|

N35UH |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥1990 |

≥25 |

263-295 |

33-37 |

≤180 |

≥7.5 |

|

N38UH |

1.23-1.29 |

12.3-12.9 |

≥915 |

≥11.5 |

≥1990 |

≥25 |

287-318 |

36-40 |

≤180 |

≥7.5 |

|

N40UH |

1.26-1.32 |

12.6-13.2 |

≥939 |

≥11.8 |

≥1990 |

≥25 |

302-334 |

38-42 |

≤180 |

≥7.5 |

|

N42UH |

1.28-1.35 |

12.8-13.5 |

≥963 |

≥12.1 |

≥1990 |

≥25 |

310-350 |

39-44 |

≤180 |

≥7.5 |

|

N45UH |

1.32-1.38 |

13.2-13.8 |

≥987 |

≥12.4 |

≥1990 |

≥25 |

334-366 |

42-46 |

≤180 |

≥7.5 |

|

N48UH |

1.37-1.42 |

13.7-14.2 |

≥1019 |

≥12.8 |

≥1910 |

≥24 |

358-390 |

45-49 |

≤180 |

≥7.5 |

|

N30EH |

1.08-1.15 |

10.8-11.5 |

≥812 |

≥10.2 |

≥2388 |

≥30 |

223-255 |

28-32 |

≤200 |

≥7.5 |

|

N33EH |

1.14-1.21 |

11.4-12.1 |

≥851 |

≥10.7 |

≥2388 |

≥30 |

247-279 |

31-35 |

≤200 |

≥7.5 |

|

N35EH |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥2388 |

≥30 |

263-295 |

33-37 |

≤200 |

≥7.5 |

|

N38EH |

1.23-1.29 |

12.3-12.9 |

≥915 |

≥11.5 |

≥2388 |

≥30 |

287-318 |

36-40 |

≤200 |

≥7.5 |

|

N40EH |

1.26-1.32 |

12.6-13.2 |

≥939 |

≥11.8 |

≥2388 |

≥30 |

302-334 |

38-42 |

≤200 |

≥7.5 |

|

N42EH |

1.28-1.35 |

12.8-13.5 |

≥963 |

≥12.1 |

≥2388 |

≥30 |

310-350 |

39-44 |

≤200 |

≥7.5 |

|

N45EH |

1.33-1.38 |

13.3-13.8 |

≥995 |

≥12.5 |

≥2308 |

≥29 |

334-366 |

42-46 |

≤200 |

≥7.5 |

|

N28AH |

1.04-1.12 |

10.4-11.2 |

≥772 |

≥9.7 |

≥2786 |

≥35 |

207-239 |

26-30 |

≤230 |

≥7.5 |

|

N30AH |

1.08-1.15 |

10.8-11.5 |

≥812 |

≥10.2 |

≥2786 |

≥35 |

223-255 |

28-32 |

≤230 |

≥7.5 |

|

N33AH |

1.14-1.21 |

11.4-12.1 |

≥852 |

≥10.7 |

≥2786 |

≥35 |

247-279 |

31-35 |

≤230 |

≥7.5 |

|

N35AH |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥2786 |

≥35 |

263-295 |

33-37 |

≤230 |

≥7.5 |

|

N38AH |

1.23-1.27 |

12.3-12.7 |

≥923 |

≥11.6 |

≥2786 |

≥35 |

287-318 |

36-40 |

≤230 |

≥7.5 |

|

N40AH |

1.26-1.31 |

12.6-13.1 |

≥939 |

≥11.8 |

≥2628 |

≥33 |

302-334 |

38-42 |

≤230 |

≥7.5 |

|

N42AH |

1.29-1.35 |

12.9-13.5 |

≥955 |

≥12.0 |

≥2628 |

≥33 |

318-350 |

40-44 |

≤230 |

≥7.5 |

|

to be conRnued |

||||||||||

|

Grade |

Remanence Induction |

Coercivity |

Intrinsic Coercivity |

๋Maximum Energy |

Working |

Density |

||||

|

Br |

HcB |

HcJ |

(BH)max |

Tw |

ρ |

|||||

|

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m³ |

MGOe |

℃ |

g/cm3 |

|

|

Diffusion Process |

||||||||||

|

G48SH |

1.37-1.42 |

13.7-14.2 |

≥1011 |

≥13 |

≥1592 |

≥20 |

358-390 |

45-49 |

≤150 |

≥7.5 |

|

G50SH |

1.40-1.45 |

14.0-14.5 |

≥1027 |

≥13.2 |

≥1592 |

≥20 |

374-406 |

47-51 |

≤150 |

≥7.5 |

|

G52SH |

1.42-1.48 |

14.2-14.8 |

≥1067 |

≥13.4 |

≥1592 |

≥20 |

390-422 |

49-53 |

≤150 |

≥7.5 |

|

G55SH |

1.46-1.51 |

14.6-15.1 |

≥1083 |

≥13.6 |

≥1592 |

≥20 |

406-438 |

51-55 |

≤150 |

≥7.5 |

|

G45UH |

1.33-1.38 |

13.3-13.8 |

≥978 |

≥12.4 |

≥1990 |

≥25 |

334-366 |

42-46 |

≤180 |

≥7.5 |

|

G48UH |

1.37-1.42 |

13.7-14.2 |

≥1027 |

≥12.9 |

≥1990 |

≥25 |

358-390 |

45-49 |

≤180 |

≥7.5 |

|

G50UH |

1.40-1.45 |

14.0-14.5 |

≥1051 |

≥13.2 |

≥1990 |

≥25 |

374-406 |

47-51 |

≤180 |

≥7.5 |

|

G52UH |

1.42-1.48 |

14.2-14.8 |

≥1067 |

≥13.4 |

≥1990 |

≥25 |

390-422 |

49-53 |

≤180 |

≥7.5 |

|

G54UH |

1.46-1.51 |

14.6-15.1 |

≥1075 |

≥13.5 |

≥1990 |

≥25 |

406-438 |

51-55 |

≤180 |

≥7.5 |

|

G40EH |

1.26-1.31 |

12.6-13.1 |

≥955 |

≥12.0 |

≥2388 |

≥30 |

302-334 |

38-42 |

≤200 |

≥7.5 |

|

G44EH |

1.29-1.35 |

12.9-13.5 |

≥971 |

≥12.2 |

≥2388 |

≥30 |

318-350 |

40-44 |

≤200 |

≥7.5 |

|

G46EH |

1.33-1.38 |

13.3-13.8 |

≥1011 |

≥12.7 |

≥2388 |

≥30 |

334-366 |

42-46 |

≤200 |

≥7.5 |

|

G48EH |

1.37-1.42 |

13.7-14.2 |

≥1027 |

≥12.9 |

≥2388 |

≥30 |

358-390 |

45-49 |

≤200 |

≥7.5 |

|

G50EH |

1.40-1.45 |

14.0-14.5 |

≥1051 |

≥13.2 |

≥2308 |

≥29 |

374-406 |

47-51 |

≤200 |

≥7.5 |

PRODUCT DESCRIPTION

Circular Disc Industrial magnet pure permanent magnet, that is, circular industrial magnet, is a pure permanent magnet with strong magnetic attraction and excellent stability. The following is a detailed introduction to this product:

Features:

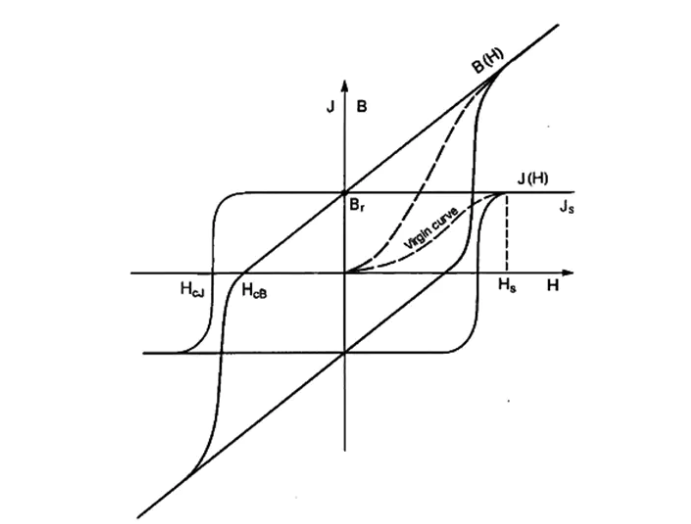

Strong magnetic attraction: Circular industrial magnets are made of high-performance rare earth materials, such as neodymium iron boron (NdFeB), etc., which have extremely high magnetic energy product and coercive force, can produce strong magnetic attraction, and are suitable for various applications that require strong adsorption. industrial applications.

Excellent stability: This kind of magnet has good temperature stability and corrosion resistance, can maintain stable magnetic properties in harsh working environments, and is not easily affected by external factors.

Diverse sizes and specifications: Circular industrial magnets can be customized with different diameters, thicknesses and magnetic pole configurations according to customer needs to meet the needs of various application scenarios.

Easy to process and install: The surface of the magnet is flat and smooth, making it easy to drill, cut, paste and other processing operations, making it convenient for customers to customize and install according to their needs.

Application areas:

Industrial machinery: used in various mechanical equipment that require magnetic adsorption, such as automated production lines, material conveying systems, magnetic separation equipment, etc.

Electronic equipment: used in the manufacturing of electronic equipment such as speakers, sensors, motors, etc. to provide stable magnetic support.

Medical equipment: used in medical equipment such as magnetic resonance imaging (MRI) to provide powerful magnetic fields for imaging diagnosis.

Environmental protection field: used for magnetic separation to separate magnetic substances in waste to achieve resource recovery and environmental protection.

Contact Us

Contact Phone

Contact E-mail

Contact Address

No.5,Aozhuangchen Industrial Park, Hangzhou, Zhejiang Province

Hot Products

The company is mainly engaged in diversified products such as space capsule integrated housing, marine ranch dedicated cabin, community integrated cabin, refrigeration and refrigeration, intelligent recuperation cabin and self-service sales cabin, and is committed to providing customers with one-stop solutions.

We are interested in our products.

Enter your contact information and we will contact you as soon as possible.