Rectangular pure permanent magnet

A rectangular pure permanent magnet is a material with a specific shape and magnetic properties. Its shape is rectangular, which gives it spatially clear boundaries and a stable structure. A pure permanent magnet means that it has the ability to spontaneously magnetize and maintain magnetism without the need for an external power source or other form of magnetization. The magnetic field of a rectangular pure permanent magnet is evenly distributed, and the magnetic lines of force form a closed loop inside the magnet, giving it unique advantages in certain applications. For example, in the fields of magnetic machinery, motors, sensors, etc., rectangular pure permanent magnets can be used as key components to provide stable and long-lasting magnetic support.

Keyword:

Rectangular pure permanent magnet

Classification:

Pure Permanent Magnet

Hot Products

| Grade | Remanence Induction | Coercivity | Intrinsic Coercivity | ๋Maximum Energy product |

Working Temperature |

Density | |||||||||||||||||

| Br | HcB | HcJ | (BH)max | Tw | ρ | ||||||||||||||||||

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m³ | MGOe | ℃ | g/cm3 | ||||||||||||||

| General Process | |||||||||||||||||||||||

| N38 | 1.23-1.30 | 12.3-13.0 | ≥876 | ≥11 | ≥955 | ≥12 | 287-318 | 36-40 | ≤80 | ≥7.5 | |||||||||||||

| N40 | 1.26-1.32 | 12.6-13.2 | ≥876 | ≥11 | ≥955 | ≥12 | 302-334 | 38-42 | ≤80 | ≥7.5 | |||||||||||||

| N42 | 1.29-1.35 | 12.9-13.5 | ≥876 | ≥11 | ≥955 | ≥12 | 318-350 | 40-44 | ≤80 | ≥7.5 | |||||||||||||

| N45 | 1.32-1.38 | 13.2-13.8 | ≥876 | ≥11 | ≥955 | ≥12 | 334-366 | 42-46 | ≤80 | ≥7.5 | |||||||||||||

| N48 | 1.37-1.43 | 13.7-14.3 | ≥876 | ≥11 | ≥955 | ≥12 | 358-390 | 45-49 | ≤80 | ≥7.5 | |||||||||||||

| N50 | 1.40-1.45 | 14.0-14.5 | ≥876 | ≥11 | ≥955 | ≥12 | 374-406 | 47-51 | ≤80 | ≥7.5 | |||||||||||||

| N52 | 1.42-1.48 | 14.2-14.8 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | ≤80 | ≥7.5 | |||||||||||||

| N55 | 1.46-1.51 | 14.6-15.1 | ≥860 | ≥10.8 | ≥955 | ≥12 | 406-438 | 51-55 | ≤80 | ≥7.5 | |||||||||||||

| N38M | 1.23-1.30 | 12.3-13.0 | ≥915 | ≥11.5 | ≥1114 | ≥14 | 287-318 | 36-40 | ≤100 | ≥7.5 | |||||||||||||

| N40M | 1.26-1.32 | 12.6-13.2 | ≥939 | ≥11.8 | ≥1114 | ≥14 | 302-334 | 38-42 | ≤100 | ≥7.5 | |||||||||||||

| N42M | 1.29-1.35 | 12.9-13.5 | ≥963 | ≥12.1 | ≥1114 | ≥14 | 318-350 | 40-44 | ≤100 | ≥7.5 | |||||||||||||

| N45M | 1.32-1.38 | 13.2-13.8 | ≥987 | ≥12.4 | ≥1114 | ≥14 | 334-366 | 42-46 | ≤100 | ≥7.5 | |||||||||||||

| N48M | 1.37-1.43 | 13.7-14.3 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 358-390 | 45-49 | ≤100 | ≥7.5 | |||||||||||||

| N50M | 1.40-1.45 | 14.0-14.5 | ≥1043 | ≥13.1 | ≥1114 | ≥14 | 374-406 | 47-51 | ≤100 | ≥7.5 | |||||||||||||

| N52M | 1.42-1.48 | 14.2-14.8 | ≥1059 | ≥13.3 | ≥1114 | ≥14 | 390-422 | 49-53 | ≤100 | ≥7.5 | |||||||||||||

| N54M | 1.46-1.51 | 14.6-15.1 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 406-438 | 51-55 | ≤100 | ≥7.5 | |||||||||||||

| N35H | 1.17-1.24 | 11.7-12.4 | ≥876 | ≥11.0 | ≥1353 | ≥17 | 263-295 | 33-37 | ≤120 | ≥7.5 | |||||||||||||

| N38H | 1.23-1.30 | 12.3-13.0 | ≥915 | ≥11.5 | ≥1353 | ≥17 | 286-318 | 36-40 | ≤120 | ≥7.5 | |||||||||||||

| N40H | 1.26-1.32 | 12.6-13.2 | ≥939 | ≥11.8 | ≥1353 | ≥17 | 302-334 | 38-42 | ≤120 | ≥7.5 | |||||||||||||

| N42H | 1.29-1.35 | 12.9-13.5 | ≥963 | ≥12.1 | ≥1353 | ≥17 | 318-350 | 40-44 | ≤120 | ≥7.5 | |||||||||||||

| N45H | 1.32-1.38 | 13.2-13.8 | ≥987 | ≥12.4 | ≥1353 | ≥17 | 334-366 | 42-46 | ≤120 | ≥7.5 | |||||||||||||

| N48H | 1.37-1.43 | 13.7-14.3 | ≥1011 | ≥12.7 | ≥1353 | ≥17 | 358-390 | 45-49 | ≤120 | ≥7.5 | |||||||||||||

| N50H | 1.40-1.45 | 14.0-14.5 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 374-406 | 47-51 | ≤120 | ≥7.5 | |||||||||||||

| N52H | 1.42-1.48 | 14.2-14.8 | ≥1059 | ≥13.3 | ≥1353 | ≥17 | 390-422 | 49-53 | ≤120 | ≥7.5 | |||||||||||||

| N33SH | 1.14-1.21 | 11.4-12.1 | ≥852 | ≥10.7 | ≥1592 | ≥20 | 247-279 | 31-35 | ≤150 | ≥7.5 | |||||||||||||

| N35SH | 1.17-1.24 | 11.7-12.4 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-295 | 33-37 | ≤150 | ≥7.5 | |||||||||||||

| N38SH | 1.23-1.29 | 12.3-12.9 | ≥915 | ≥11.5 | ≥1592 | ≥20 | 287-318 | 36-40 | ≤150 | ≥7.5 | |||||||||||||

| N40SH | 1.26-1.32 | 12.6-13.2 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-334 | 38-42 | ≤150 | ≥7.5 | |||||||||||||

| N42SH | 1.29-1.35 | 12.9-13.5 | ≥963 | ≥12.1 | ≥1592 | ≥20 | 318-350 | 40-44 | ≤150 | ≥7.5 | |||||||||||||

| N45SH | 1.32-1.38 | 13.2-13.8 | ≥987 | ≥12.4 | ≥1592 | ≥20 | 334-366 | 42-46 | ≤150 | ≥7.5 | |||||||||||||

| to be conRnued | |||||||||||||||||||||||

|

Grade |

Coercivity, Intrinsic coercivity |

Coercivity |

Intrinsic Coercivity |

Maximum Energy product |

WorkingTemperature |

Density |

||||

|

Br |

HcB |

HcJ |

(BH)max |

Tw |

ρ |

|||||

|

Grade |

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m³ |

MGOe |

℃ |

g/cm3 |

|

N48SH |

1.37-1.43 |

13.7-14.3 |

≥1011 |

≥12.7 |

≥1592 |

≥20 |

358-390 |

45-49 |

≤150 |

≥7.5 |

|

N50SH |

1.40-1.45 |

14.0-14.5 |

≥1027 |

≥12.9 |

≥1592 |

≥20 |

374-406 |

47-51 |

≤150 |

≥7.5 |

|

N52SH |

1.42-1.48 |

14.2-14.8 |

≥1035 |

≥13 |

≥1512 |

≥19 |

390-422 |

49-53 |

≤150 |

≥7.5 |

|

N30UH |

1.08-1.13 |

10.8-11.3 |

≥796 |

≥10.0 |

≥1990 |

≥25 |

223-255 |

28-31 |

≤180 |

≥7.5 |

|

N33UH |

1.14-1.18 |

11.4-11.8 |

≥852 |

≥10.5 |

≥1990 |

≥25 |

247-279 |

31-35 |

≤180 |

≥7.5 |

|

N35UH |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥1990 |

≥25 |

263-295 |

33-37 |

≤180 |

≥7.5 |

|

N38UH |

1.23-1.29 |

12.3-12.9 |

≥915 |

≥11.5 |

≥1990 |

≥25 |

287-318 |

36-40 |

≤180 |

≥7.5 |

|

N40UH |

1.26-1.32 |

12.6-13.2 |

≥939 |

≥11.8 |

≥1990 |

≥25 |

302-334 |

38-42 |

≤180 |

≥7.5 |

|

N42UH |

1.28-1.35 |

12.8-13.5 |

≥963 |

≥12.1 |

≥1990 |

≥25 |

310-350 |

39-44 |

≤180 |

≥7.5 |

|

N45UH |

1.32-1.38 |

13.2-13.8 |

≥987 |

≥12.4 |

≥1990 |

≥25 |

334-366 |

42-46 |

≤180 |

≥7.5 |

|

N48UH |

1.37-1.42 |

13.7-14.2 |

≥1019 |

≥12.8 |

≥1910 |

≥24 |

358-390 |

45-49 |

≤180 |

≥7.5 |

|

N30EH |

1.08-1.15 |

10.8-11.5 |

≥812 |

≥10.2 |

≥2388 |

≥30 |

223-255 |

28-32 |

≤200 |

≥7.5 |

|

N33EH |

1.14-1.21 |

11.4-12.1 |

≥851 |

≥10.7 |

≥2388 |

≥30 |

247-279 |

31-35 |

≤200 |

≥7.5 |

|

N35EH |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥2388 |

≥30 |

263-295 |

33-37 |

≤200 |

≥7.5 |

|

N38EH |

1.23-1.29 |

12.3-12.9 |

≥915 |

≥11.5 |

≥2388 |

≥30 |

287-318 |

36-40 |

≤200 |

≥7.5 |

|

N40EH |

1.26-1.32 |

12.6-13.2 |

≥939 |

≥11.8 |

≥2388 |

≥30 |

302-334 |

38-42 |

≤200 |

≥7.5 |

|

N42EH |

1.28-1.35 |

12.8-13.5 |

≥963 |

≥12.1 |

≥2388 |

≥30 |

310-350 |

39-44 |

≤200 |

≥7.5 |

|

N45EH |

1.33-1.38 |

13.3-13.8 |

≥995 |

≥12.5 |

≥2308 |

≥29 |

334-366 |

42-46 |

≤200 |

≥7.5 |

|

N28AH |

1.04-1.12 |

10.4-11.2 |

≥772 |

≥9.7 |

≥2786 |

≥35 |

207-239 |

26-30 |

≤230 |

≥7.5 |

|

N30AH |

1.08-1.15 |

10.8-11.5 |

≥812 |

≥10.2 |

≥2786 |

≥35 |

223-255 |

28-32 |

≤230 |

≥7.5 |

|

N33AH |

1.14-1.21 |

11.4-12.1 |

≥852 |

≥10.7 |

≥2786 |

≥35 |

247-279 |

31-35 |

≤230 |

≥7.5 |

|

N35AH |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥2786 |

≥35 |

263-295 |

33-37 |

≤230 |

≥7.5 |

|

N38AH |

1.23-1.27 |

12.3-12.7 |

≥923 |

≥11.6 |

≥2786 |

≥35 |

287-318 |

36-40 |

≤230 |

≥7.5 |

|

N40AH |

1.26-1.31 |

12.6-13.1 |

≥939 |

≥11.8 |

≥2628 |

≥33 |

302-334 |

38-42 |

≤230 |

≥7.5 |

|

N42AH |

1.29-1.35 |

12.9-13.5 |

≥955 |

≥12.0 |

≥2628 |

≥33 |

318-350 |

40-44 |

≤230 |

≥7.5 |

|

to be conRnued |

||||||||||

|

Grade |

Remanence Induction |

Coercivity |

Intrinsic Coercivity |

๋Maximum Energy |

Working |

Density |

||||

|

Br |

HcB |

HcJ |

(BH)max |

Tw |

ρ |

|||||

|

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m³ |

MGOe |

℃ |

g/cm3 |

|

|

Diffusion Process |

||||||||||

|

G48SH |

1.37-1.42 |

13.7-14.2 |

≥1011 |

≥13 |

≥1592 |

≥20 |

358-390 |

45-49 |

≤150 |

≥7.5 |

|

G50SH |

1.40-1.45 |

14.0-14.5 |

≥1027 |

≥13.2 |

≥1592 |

≥20 |

374-406 |

47-51 |

≤150 |

≥7.5 |

|

G52SH |

1.42-1.48 |

14.2-14.8 |

≥1067 |

≥13.4 |

≥1592 |

≥20 |

390-422 |

49-53 |

≤150 |

≥7.5 |

|

G55SH |

1.46-1.51 |

14.6-15.1 |

≥1083 |

≥13.6 |

≥1592 |

≥20 |

406-438 |

51-55 |

≤150 |

≥7.5 |

|

G45UH |

1.33-1.38 |

13.3-13.8 |

≥978 |

≥12.4 |

≥1990 |

≥25 |

334-366 |

42-46 |

≤180 |

≥7.5 |

|

G48UH |

1.37-1.42 |

13.7-14.2 |

≥1027 |

≥12.9 |

≥1990 |

≥25 |

358-390 |

45-49 |

≤180 |

≥7.5 |

|

G50UH |

1.40-1.45 |

14.0-14.5 |

≥1051 |

≥13.2 |

≥1990 |

≥25 |

374-406 |

47-51 |

≤180 |

≥7.5 |

|

G52UH |

1.42-1.48 |

14.2-14.8 |

≥1067 |

≥13.4 |

≥1990 |

≥25 |

390-422 |

49-53 |

≤180 |

≥7.5 |

|

G54UH |

1.46-1.51 |

14.6-15.1 |

≥1075 |

≥13.5 |

≥1990 |

≥25 |

406-438 |

51-55 |

≤180 |

≥7.5 |

|

G40EH |

1.26-1.31 |

12.6-13.1 |

≥955 |

≥12.0 |

≥2388 |

≥30 |

302-334 |

38-42 |

≤200 |

≥7.5 |

|

G44EH |

1.29-1.35 |

12.9-13.5 |

≥971 |

≥12.2 |

≥2388 |

≥30 |

318-350 |

40-44 |

≤200 |

≥7.5 |

|

G46EH |

1.33-1.38 |

13.3-13.8 |

≥1011 |

≥12.7 |

≥2388 |

≥30 |

334-366 |

42-46 |

≤200 |

≥7.5 |

|

G48EH |

1.37-1.42 |

13.7-14.2 |

≥1027 |

≥12.9 |

≥2388 |

≥30 |

358-390 |

45-49 |

≤200 |

≥7.5 |

|

G50EH |

1.40-1.45 |

14.0-14.5 |

≥1051 |

≥13.2 |

≥2308 |

≥29 |

374-406 |

47-51 |

≤200 |

≥7.5 |

PRODUCT DESCRIPTION

Rectangular pure permanent magnet is a product with specific shape and magnetic properties, which has a wide range of applications in multiple fields. The following is a detailed introduction to rectangular pure permanent magnets:

Shape and structure:

Rectangular pure permanent magnets, as the name suggests, are mainly rectangular in shape. This shape gives them a stable structure and a high degree of processability.

It is made of high-purity magnetic material, ensuring its excellent magnetic properties.

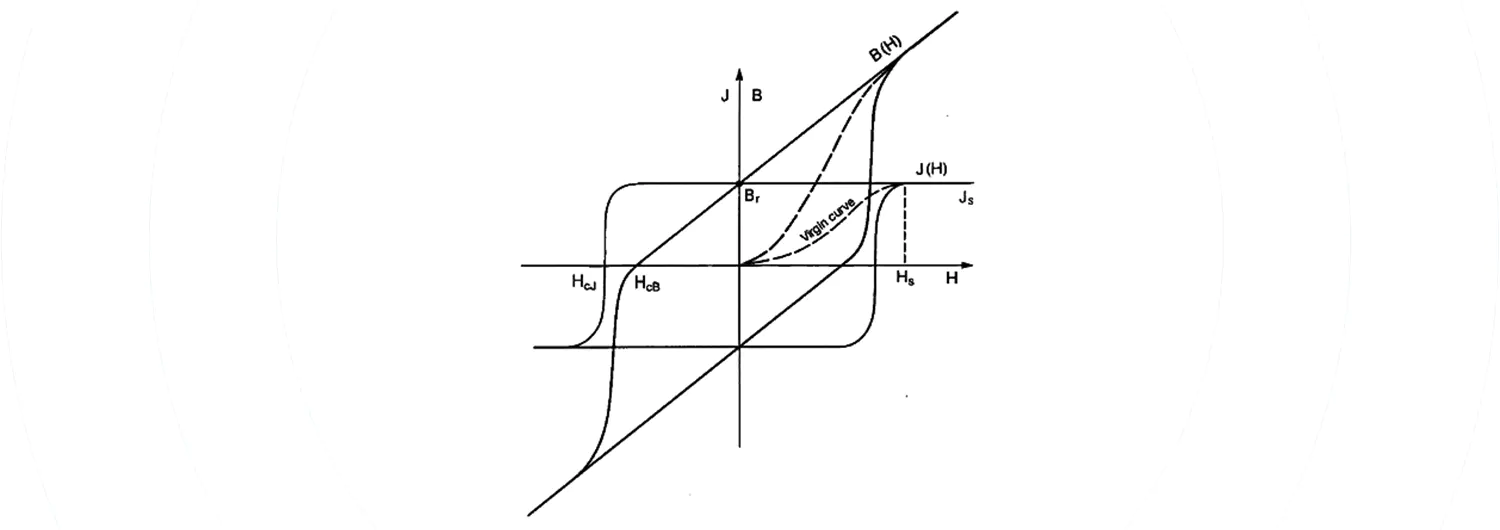

Magnetic properties:

Rectangular pure permanent magnets have strong magnetic fields and stable magnetic properties, and can maintain their magnetism unchanged for a long time.

Its magnetic field is evenly distributed and can meet the needs of various precision applications.

Application areas:

Due to their excellent magnetic properties and stable structure, rectangular pure permanent magnets are widely used in motors, sensors, medical equipment, instrumentation and other fields.

In the field of motors, it can serve as the magnetic pole of the motor, providing a stable magnetic field to ensure the normal operation of the motor.

In the field of sensors, it can be used as a sensitive element to detect changes in magnetic fields to achieve various automated controls.

Advantages and features:

Rectangular pure permanent magnets have the advantages of high magnetic energy product, high coercivity, and low temperature coefficient.

Compared with permanent magnets of other shapes, rectangular pure permanent magnets are easier to orient and magnetize, making production and application easier.

At the same time, due to its high purity and low impurities, it has better stability and reliability.

As a manufacturer, producer and manufacturer of rectangular pure permanent magnets, you may also need to pay attention to the production process, quality control, and market application trends of the products. By continuously optimizing production processes, improving product quality, and expanding application areas, you can better meet market demand and enhance the competitiveness of your company.

Contact Us

Contact Phone

Contact E-mail

Contact Address

No.5,Aozhuangchen Industrial Park, Hangzhou, Zhejiang Province

Hot Products

The company is mainly engaged in diversified products such as space capsule integrated housing, marine ranch dedicated cabin, community integrated cabin, refrigeration and refrigeration, intelligent recuperation cabin and self-service sales cabin, and is committed to providing customers with one-stop solutions.

We are interested in our products.

Enter your contact information and we will contact you as soon as possible.