Super strong O ring shape pure permanent magnet

Super strong O ring shape pure permanent magnet, this magnet uses high-purity rare earth materials to create super strong magnetic force, the O-ring design is unique, perfect for a variety of installation needs. Widely used in electronics, machinery, medical and other fields. Stable, reliable and durable.

Keyword:

Super strong O ring shape pure permanent magnet

Classification:

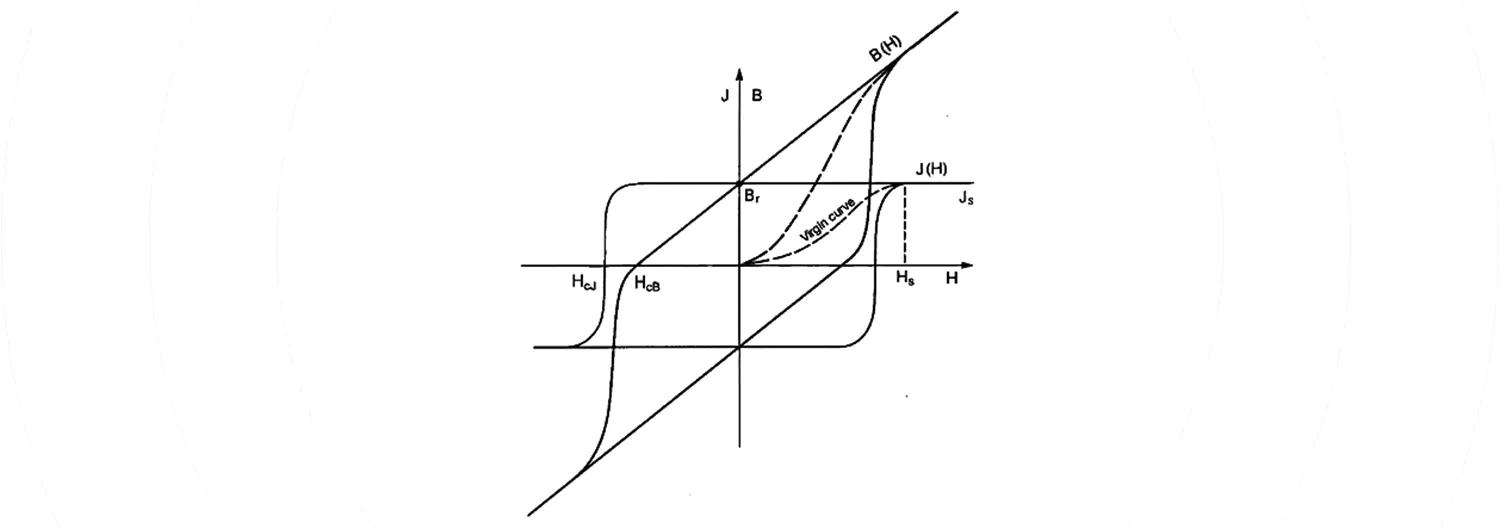

Pure Permanent Magnet

|

Grade |

Remanence Induction |

Coercivity |

Intrinsic Coercivity |

๋Maximum Energy |

Working |

Density |

||||

|

Br |

HcB |

HcJ |

(BH)max |

Tw |

ρ |

|||||

|

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m³ |

MGOe |

℃ |

g/cm3 |

|

|

General Process |

||||||||||

|

N38 |

1.23-1.30 |

12.3-13.0 |

≥876 |

≥11 |

≥955 |

≥12 |

287-318 |

36-40 |

≤80 |

≥7.5 |

|

N40 |

1.26-1.32 |

12.6-13.2 |

≥876 |

≥11 |

≥955 |

≥12 |

302-334 |

38-42 |

≤80 |

≥7.5 |

|

N42 |

1.29-1.35 |

12.9-13.5 |

≥876 |

≥11 |

≥955 |

≥12 |

318-350 |

40-44 |

≤80 |

≥7.5 |

|

N45 |

1.32-1.38 |

13.2-13.8 |

≥876 |

≥11 |

≥955 |

≥12 |

334-366 |

42-46 |

≤80 |

≥7.5 |

|

N48 |

1.37-1.43 |

13.7-14.3 |

≥876 |

≥11 |

≥955 |

≥12 |

358-390 |

45-49 |

≤80 |

≥7.5 |

|

N50 |

1.40-1.45 |

14.0-14.5 |

≥876 |

≥11 |

≥955 |

≥12 |

374-406 |

47-51 |

≤80 |

≥7.5 |

|

N52 |

1.42-1.48 |

14.2-14.8 |

≥836 |

≥10.5 |

≥876 |

≥11 |

390-422 |

49-53 |

≤80 |

≥7.5 |

|

N55 |

1.46-1.51 |

14.6-15.1 |

≥860 |

≥10.8 |

≥955 |

≥12 |

406-438 |

51-55 |

≤80 |

≥7.5 |

|

N38M |

1.23-1.30 |

12.3-13.0 |

≥915 |

≥11.5 |

≥1114 |

≥14 |

287-318 |

36-40 |

≤100 |

≥7.5 |

|

N40M |

1.26-1.32 |

12.6-13.2 |

≥939 |

≥11.8 |

≥1114 |

≥14 |

302-334 |

38-42 |

≤100 |

≥7.5 |

|

N42M |

1.29-1.35 |

12.9-13.5 |

≥963 |

≥12.1 |

≥1114 |

≥14 |

318-350 |

40-44 |

≤100 |

≥7.5 |

|

N45M |

1.32-1.38 |

13.2-13.8 |

≥987 |

≥12.4 |

≥1114 |

≥14 |

334-366 |

42-46 |

≤100 |

≥7.5 |

|

N48M |

1.37-1.43 |

13.7-14.3 |

≥1019 |

≥12.8 |

≥1114 |

≥14 |

358-390 |

45-49 |

≤100 |

≥7.5 |

|

N50M |

1.40-1.45 |

14.0-14.5 |

≥1043 |

≥13.1 |

≥1114 |

≥14 |

374-406 |

47-51 |

≤100 |

≥7.5 |

|

N52M |

1.42-1.48 |

14.2-14.8 |

≥1059 |

≥13.3 |

≥1114 |

≥14 |

390-422 |

49-53 |

≤100 |

≥7.5 |

|

N54M |

1.46-1.51 |

14.6-15.1 |

≥995 |

≥12.5 |

≥1035 |

≥13 |

406-438 |

51-55 |

≤100 |

≥7.5 |

|

N35H |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥1353 |

≥17 |

263-295 |

33-37 |

≤120 |

≥7.5 |

|

N38H |

1.23-1.30 |

12.3-13.0 |

≥915 |

≥11.5 |

≥1353 |

≥17 |

286-318 |

36-40 |

≤120 |

≥7.5 |

|

N40H |

1.26-1.32 |

12.6-13.2 |

≥939 |

≥11.8 |

≥1353 |

≥17 |

302-334 |

38-42 |

≤120 |

≥7.5 |

|

N42H |

1.29-1.35 |

12.9-13.5 |

≥963 |

≥12.1 |

≥1353 |

≥17 |

318-350 |

40-44 |

≤120 |

≥7.5 |

|

N45H |

1.32-1.38 |

13.2-13.8 |

≥987 |

≥12.4 |

≥1353 |

≥17 |

334-366 |

42-46 |

≤120 |

≥7.5 |

|

N48H |

1.37-1.43 |

13.7-14.3 |

≥1011 |

≥12.7 |

≥1353 |

≥17 |

358-390 |

45-49 |

≤120 |

≥7.5 |

|

N50H |

1.40-1.45 |

14.0-14.5 |

≥1027 |

≥12.9 |

≥1353 |

≥17 |

374-406 |

47-51 |

≤120 |

≥7.5 |

|

N52H |

1.42-1.48 |

14.2-14.8 |

≥1059 |

≥13.3 |

≥1353 |

≥17 |

390-422 |

49-53 |

≤120 |

≥7.5 |

|

N33SH |

1.14-1.21 |

11.4-12.1 |

≥852 |

≥10.7 |

≥1592 |

≥20 |

247-279 |

31-35 |

≤150 |

≥7.5 |

|

N35SH |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥1592 |

≥20 |

263-295 |

33-37 |

≤150 |

≥7.5 |

|

N38SH |

1.23-1.29 |

12.3-12.9 |

≥915 |

≥11.5 |

≥1592 |

≥20 |

287-318 |

36-40 |

≤150 |

≥7.5 |

|

N40SH |

1.26-1.32 |

12.6-13.2 |

≥939 |

≥11.8 |

≥1592 |

≥20 |

302-334 |

38-42 |

≤150 |

≥7.5 |

|

N42SH |

1.29-1.35 |

12.9-13.5 |

≥963 |

≥12.1 |

≥1592 |

≥20 |

318-350 |

40-44 |

≤150 |

≥7.5 |

|

N45SH |

1.32-1.38 |

13.2-13.8 |

≥987 |

≥12.4 |

≥1592 |

≥20 |

334-366 |

42-46 |

≤150 |

≥7.5 |

|

to be conRnued |

||||||||||

|

Grade |

Remanence Induction |

Coercivity |

Intrinsic Coercivity |

Maximum Energy product |

WorkingTemperature |

Density |

||||

|

Br |

HcB |

HcJ |

(BH)max |

Tw |

ρ |

|||||

|

Grade |

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m³ |

MGOe |

℃ |

g/cm3 |

|

N48SH |

1.37-1.43 |

13.7-14.3 |

≥1011 |

≥12.7 |

≥1592 |

≥20 |

358-390 |

45-49 |

≤150 |

≥7.5 |

|

N50SH |

1.40-1.45 |

14.0-14.5 |

≥1027 |

≥12.9 |

≥1592 |

≥20 |

374-406 |

47-51 |

≤150 |

≥7.5 |

|

N52SH |

1.42-1.48 |

14.2-14.8 |

≥1035 |

≥13 |

≥1512 |

≥19 |

390-422 |

49-53 |

≤150 |

≥7.5 |

|

N30UH |

1.08-1.13 |

10.8-11.3 |

≥796 |

≥10.0 |

≥1990 |

≥25 |

223-255 |

28-31 |

≤180 |

≥7.5 |

|

N33UH |

1.14-1.18 |

11.4-11.8 |

≥852 |

≥10.5 |

≥1990 |

≥25 |

247-279 |

31-35 |

≤180 |

≥7.5 |

|

N35UH |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥1990 |

≥25 |

263-295 |

33-37 |

≤180 |

≥7.5 |

|

N38UH |

1.23-1.29 |

12.3-12.9 |

≥915 |

≥11.5 |

≥1990 |

≥25 |

287-318 |

36-40 |

≤180 |

≥7.5 |

|

N40UH |

1.26-1.32 |

12.6-13.2 |

≥939 |

≥11.8 |

≥1990 |

≥25 |

302-334 |

38-42 |

≤180 |

≥7.5 |

|

N42UH |

1.28-1.35 |

12.8-13.5 |

≥963 |

≥12.1 |

≥1990 |

≥25 |

310-350 |

39-44 |

≤180 |

≥7.5 |

|

N45UH |

1.32-1.38 |

13.2-13.8 |

≥987 |

≥12.4 |

≥1990 |

≥25 |

334-366 |

42-46 |

≤180 |

≥7.5 |

|

N48UH |

1.37-1.42 |

13.7-14.2 |

≥1019 |

≥12.8 |

≥1910 |

≥24 |

358-390 |

45-49 |

≤180 |

≥7.5 |

|

N30EH |

1.08-1.15 |

10.8-11.5 |

≥812 |

≥10.2 |

≥2388 |

≥30 |

223-255 |

28-32 |

≤200 |

≥7.5 |

|

N33EH |

1.14-1.21 |

11.4-12.1 |

≥851 |

≥10.7 |

≥2388 |

≥30 |

247-279 |

31-35 |

≤200 |

≥7.5 |

|

N35EH |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥2388 |

≥30 |

263-295 |

33-37 |

≤200 |

≥7.5 |

|

N38EH |

1.23-1.29 |

12.3-12.9 |

≥915 |

≥11.5 |

≥2388 |

≥30 |

287-318 |

36-40 |

≤200 |

≥7.5 |

|

N40EH |

1.26-1.32 |

12.6-13.2 |

≥939 |

≥11.8 |

≥2388 |

≥30 |

302-334 |

38-42 |

≤200 |

≥7.5 |

|

N42EH |

1.28-1.35 |

12.8-13.5 |

≥963 |

≥12.1 |

≥2388 |

≥30 |

310-350 |

39-44 |

≤200 |

≥7.5 |

|

N45EH |

1.33-1.38 |

13.3-13.8 |

≥995 |

≥12.5 |

≥2308 |

≥29 |

334-366 |

42-46 |

≤200 |

≥7.5 |

|

N28AH |

1.04-1.12 |

10.4-11.2 |

≥772 |

≥9.7 |

≥2786 |

≥35 |

207-239 |

26-30 |

≤230 |

≥7.5 |

|

N30AH |

1.08-1.15 |

10.8-11.5 |

≥812 |

≥10.2 |

≥2786 |

≥35 |

223-255 |

28-32 |

≤230 |

≥7.5 |

|

N33AH |

1.14-1.21 |

11.4-12.1 |

≥852 |

≥10.7 |

≥2786 |

≥35 |

247-279 |

31-35 |

≤230 |

≥7.5 |

|

N35AH |

1.17-1.24 |

11.7-12.4 |

≥876 |

≥11.0 |

≥2786 |

≥35 |

263-295 |

33-37 |

≤230 |

≥7.5 |

|

N38AH |

1.23-1.27 |

12.3-12.7 |

≥923 |

≥11.6 |

≥2786 |

≥35 |

287-318 |

36-40 |

≤230 |

≥7.5 |

|

N40AH |

1.26-1.31 |

12.6-13.1 |

≥939 |

≥11.8 |

≥2628 |

≥33 |

302-334 |

38-42 |

≤230 |

≥7.5 |

|

N42AH |

1.29-1.35 |

12.9-13.5 |

≥955 |

≥12.0 |

≥2628 |

≥33 |

318-350 |

40-44 |

≤230 |

≥7.5 |

|

to be conRnued |

||||||||||

|

Grade |

Remanence Induction |

Coercivity |

Intrinsic Coercivity |

๋Maximum Energy |

Working |

Density |

||||

|

Br |

HcB |

HcJ |

(BH)max |

Tw |

ρ |

|||||

|

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m³ |

MGOe |

℃ |

g/cm3 |

|

|

Diffusion Process |

||||||||||

|

G48SH |

1.37-1.42 |

13.7-14.2 |

≥1011 |

≥13 |

≥1592 |

≥20 |

358-390 |

45-49 |

≤150 |

≥7.5 |

|

G50SH |

1.40-1.45 |

14.0-14.5 |

≥1027 |

≥13.2 |

≥1592 |

≥20 |

374-406 |

47-51 |

≤150 |

≥7.5 |

|

G52SH |

1.42-1.48 |

14.2-14.8 |

≥1067 |

≥13.4 |

≥1592 |

≥20 |

390-422 |

49-53 |

≤150 |

≥7.5 |

|

G55SH |

1.46-1.51 |

14.6-15.1 |

≥1083 |

≥13.6 |

≥1592 |

≥20 |

406-438 |

51-55 |

≤150 |

≥7.5 |

|

G45UH |

1.33-1.38 |

13.3-13.8 |

≥978 |

≥12.4 |

≥1990 |

≥25 |

334-366 |

42-46 |

≤180 |

≥7.5 |

|

G48UH |

1.37-1.42 |

13.7-14.2 |

≥1027 |

≥12.9 |

≥1990 |

≥25 |

358-390 |

45-49 |

≤180 |

≥7.5 |

|

G50UH |

1.40-1.45 |

14.0-14.5 |

≥1051 |

≥13.2 |

≥1990 |

≥25 |

374-406 |

47-51 |

≤180 |

≥7.5 |

|

G52UH |

1.42-1.48 |

14.2-14.8 |

≥1067 |

≥13.4 |

≥1990 |

≥25 |

390-422 |

49-53 |

≤180 |

≥7.5 |

|

G54UH |

1.46-1.51 |

14.6-15.1 |

≥1075 |

≥13.5 |

≥1990 |

≥25 |

406-438 |

51-55 |

≤180 |

≥7.5 |

|

G40EH |

1.26-1.31 |

12.6-13.1 |

≥955 |

≥12.0 |

≥2388 |

≥30 |

302-334 |

38-42 |

≤200 |

≥7.5 |

|

G44EH |

1.29-1.35 |

12.9-13.5 |

≥971 |

≥12.2 |

≥2388 |

≥30 |

318-350 |

40-44 |

≤200 |

≥7.5 |

|

G46EH |

1.33-1.38 |

13.3-13.8 |

≥1011 |

≥12.7 |

≥2388 |

≥30 |

334-366 |

42-46 |

≤200 |

≥7.5 |

|

G48EH |

1.37-1.42 |

13.7-14.2 |

≥1027 |

≥12.9 |

≥2388 |

≥30 |

358-390 |

45-49 |

≤200 |

≥7.5 |

|

G50EH |

1.40-1.45 |

14.0-14.5 |

≥1051 |

≥13.2 |

≥2308 |

≥29 |

374-406 |

47-51 |

≤200 |

≥7.5 |

PRODUCT DESCRIPTION

Super strong O ring shape pure permanent magnet, with magnetic properties, stable magnetic field and unique O ring design, is used in many industries and application fields. This permanent magnet is made of high-purity materials, ensuring its super strong magnetic force and long-term durability. It is an indispensable key component for various precision instruments, automation equipment, motors and sensors.

Product features:

Super strong magnetic force: Made of high-quality rare earth materials and precision processed, it has a magnetic force far exceeding that of ordinary magnets, can easily adsorb and fix heavy objects, and meet various high-strength requirements.

High purity and stable performance: The raw materials with extremely high purity are selected to ensure the stable and reliable performance of the magnet, and it is not easy to demagnetize after long-term use, and is suitable for various harsh environments.

O ring design: The unique O ring shape design is not only beautiful and generous, but also easier to install and fix. It can fit various curved surfaces and irregular shapes tightly and improve the use efficiency.

Wide application: It is widely used in electronics, communications, medical, machinery, aerospace and other fields. It is an ideal choice for motors, sensors, speakers, magnetic levitation and other equipment.

Environmentally friendly materials: All materials meet environmental standards, are non-toxic and harmless, recyclable, and in line with modern green production concepts.

Precautions for use:

Do not bring magnets close to magnetic storage media (such as hard disks, tapes, etc.) to avoid data loss.

Avoid exposing magnets to high temperatures or strong magnetic fields to avoid affecting their performance.

Please wear protective gloves when using to prevent hand injuries.

Contact Us

Contact Phone

Contact E-mail

Contact Address

No.5,Aozhuangchen Industrial Park, Hangzhou, Zhejiang Province

Hot Products

The company is mainly engaged in diversified products such as space capsule integrated housing, marine ranch dedicated cabin, community integrated cabin, refrigeration and refrigeration, intelligent recuperation cabin and self-service sales cabin, and is committed to providing customers with one-stop solutions.

We are interested in our products.

Enter your contact information and we will contact you as soon as possible.